Berlin, April 2025

Klosterfrau Berlin strengthens Germany as a pharmaceutical location

Source: Klosterfrau Healthcare Group

To secure existing jobs and create new ones, the Klosterfrau Group invested approximately €60 million in the construction of modern production facilities at its Berlin site over the past four years. These facilities feature innovative sustainability technologies for energy saving, efficiency, and recovery. The first sub-project, a new highly automated facility with 1,200 m² of cleanroom space for innovative pre-filled syringe systems, will commence production in June. The new "medicinal lozenge" building will open two years later. Both investments will contribute to meeting the increasing demand from patients and ensuring the company's long-term sustainability.

The history of the production facility began in 1971 with 24 copper stills, in which Melissengeist was distilled at the Berlin-Marienfelde site. Over the past decades, Klosterfrau Berlin GmbH has developed into an integrated pharmaceutical industrial site. Today, the pharmaceutical company produces medicated lozenges, liquid dosage forms, and sterile single-use syringes on 45,000 square meters, adhering to the strictest GMP and FDA (Good Manufacturing Practice & Food and Drug Administration) guidelines. The company is the largest production site in the Klosterfrau Group. Sustainable production and innovation in new technologies are key drivers for the employees at Klosterfrau Berlin. The company has always been characterized by a culture of continually combining tradition and modernity. Production takes place at three facilities in Berlin:

Facility 1: Sterile pre-filled syringes such as Instillagel®, VESOXX®

Facility 2: Liquid medications such as Klosterfrau Melissengeist®, nasic® nasal spray, Bronchi-cum® cough syrups

Facility 3: Medicated lozenges such as neo-angin®, anginetten®

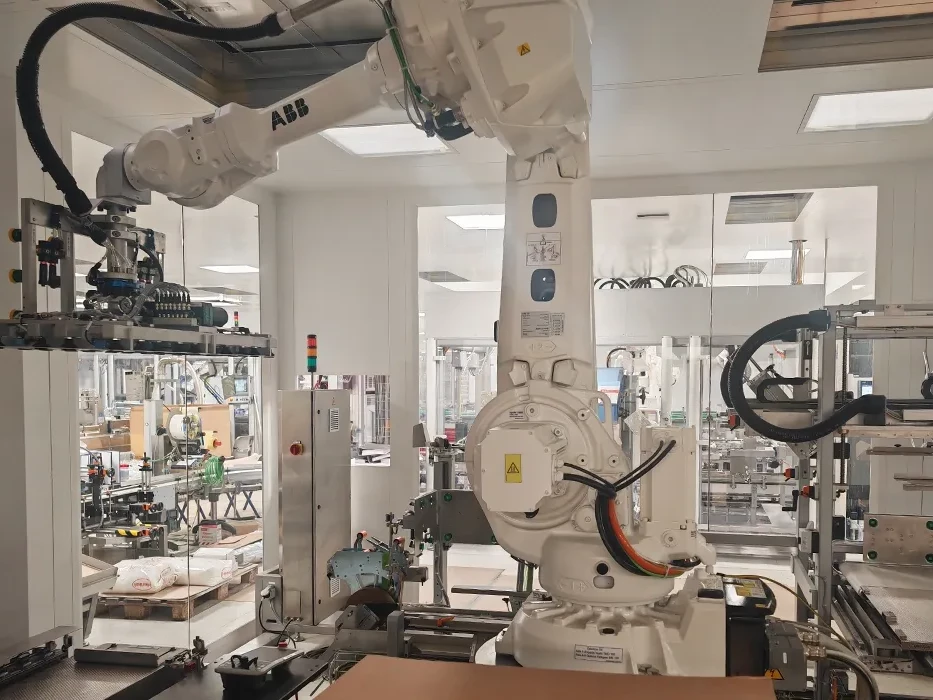

The image shows: Leading German engineering firms working closely with the Klosterfrau team are driving innovation, here at the commissioning of the bottling station.

Numerous guests at the opening ceremony

On Friday, April 11, 2025, the day finally arrived: Together with partners from industry, associations, and government agencies, the new sterile syringe production facility was officially opened. In addition to the obligatory cutting of the red ribbon, all guests had the opportunity to tour the new premises and have the various machines explained to them by the staff. Afterwards, everyone was invited to an open discussion with finger food, which provided time for networking and rounded off the program. Dr. Stefan Koch is optimistic about the opening of the syringe plant: "With the opening of our new sterile production facility, we are demonstrating that the combination of state-of-the-art manufacturing technology coupled with an innovative energy concept is still possible in Germany. We are confident that these investments will further strengthen Berlin as a business location."

Planned Investments and Their Objectives

The new, highly automated sterile production facility with 1,200 m² of cleanroom space for innovative pre-filled syringe systems will commence production as early as June. The investment required for this sub-project is €25 million, with an annual production volume of up to 50 million syringes. The majority of these syringes will be distributed internationally by Farco-Pharma GmbH (Cologne). "The facility will be equipped with intelligent control systems for the efficient use of electricity (high-efficiency electric motors, sensors to monitor energy consumption, dimmable LED lighting for individual areas), heat (heat recovery), and cooling (free cooling without the use of refrigerants)," said Christoph Klaus. For him, the event is a very special occasion, as it is his last in his position as Managing Director. He ceremoniously presents Dr. Marcel Oster with the Berlin Bear as a symbolic handover gesture. Oster will continue his work as managing director at the Berlin location from now on.

The image shows: Christoph Klaus (former Managing Director of Klosterfrau Berlin GmbH, pictured on the right) presents the Berlin Bear to Dr. Marcel Oster (successor and new Managing Director) as a symbolic gesture of handover.

The image shows: Spacious premises with LED lighting, daylight and many windows to improve the employees' sense of space.

The image shows that robotics is firmly integrated into many parts of the new factory, as exemplified here by the packaging of shipping cartons.

Quick Facts

- To secure existing jobs and create new ones, the Klosterfrau Group is investing approximately €60 million over four years in the construction of modern production facilities at its Berlin site.

- The facilities feature innovative sustainability technologies for energy saving, efficiency, and recovery.

- As the first sub-project, the new highly automated facility with 1,200 m² of cleanroom space for innovative pre-filled syringe systems will commence production in June. The opening of the new "medicinal lozenges" building will follow two years later.

- Both investments will contribute to meeting the increasing demand from patients and customers in the long term.

The Klosterfrau Group Award

Since 2001, the International Klosterfrau Group Award for Research of Airway Diseases in Childhood has been awarded annually on the initiative of Prof. Dr. med. Dr. h.c. Dietrich Reinhardt, the International Klosterfrau Group Award for Research of Airway Diseases in Childhood has been awarded annually. Valued at 30,000 euros, the prize honors scientists whose research has significantly contributed to the basic research, diagnosis, and treatment of childhood asthma.