Introducing Klosterfrau Berlin

The Klosterfrau Berlin GmbH is a central production site of the group, combining tradition with state-of-the-art manufacturing technology. In Berlin-Marienfelde, liquids, lozenges, and sterile, pre-filled syringes are produced.

Klosterfrau Berlin production

Klosterfrau Berlin production

Klosterfrau Berlin production

Klosterfrau Berlin production

Klosterfrau Berlin

From Cologne to Berlin – A Success Story

At the end of the 1960s, the production and storage capacities at the Cologne headquarters became too small. Since expansion in Cologne was not possible, the company took a bold step: In 1971, a new plant was established at the former zonal border in Berlin, relocating a significant portion of production there. Over the decades, the site has been continuously expanded and equipped with the latest manufacturing technologies.

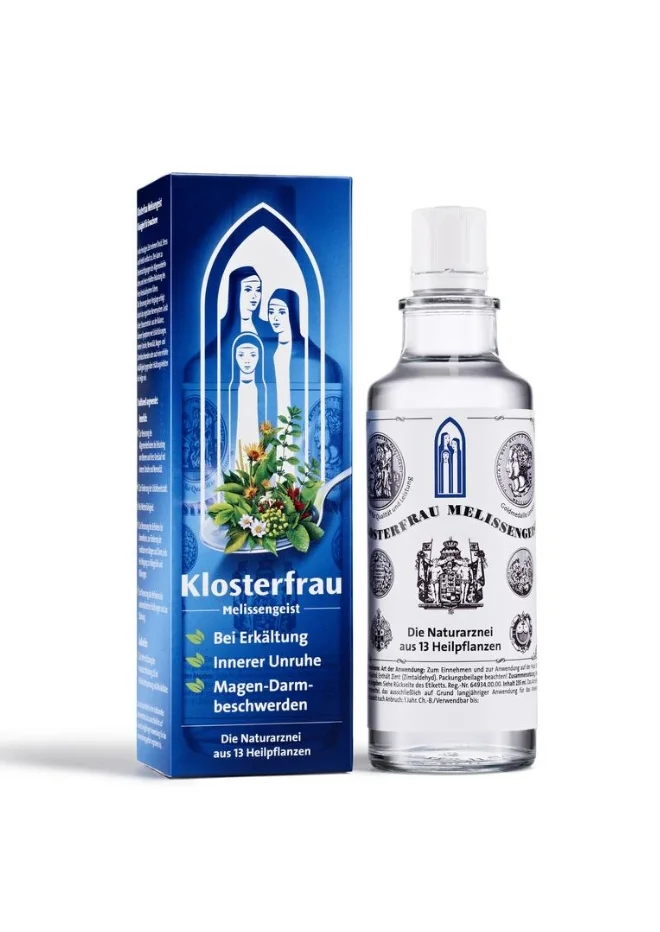

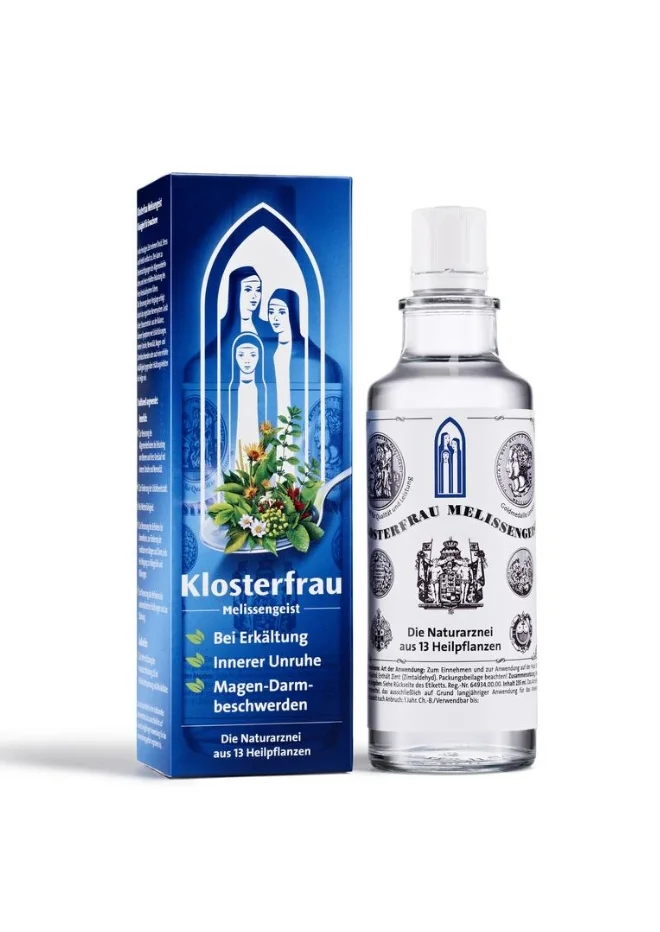

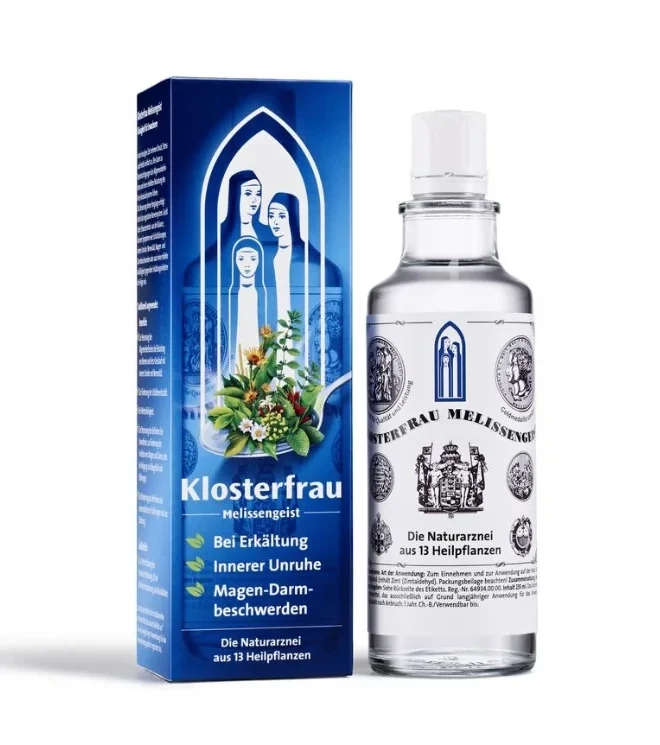

Liquids – The Heart of Tradition

In the liquids division, distillates, nasal sprays, juices, and drops of well-known brands such as Bronchicum, Monapax, and Nasic are produced.

The core of this division is the distillation stills for the trusted Klosterfrau Melissengeist. From sourcing 13 medicinal plants to market release, expert teams monitor the entire supply chain.

In late 2018, a new filling line was commissioned for Melissengeist, specially designed for explosive atmospheres due to the product's alcohol content. Following the acquisition of Sanofi’s Nattermann products in 2016, a fully automated line for cough syrups and drops was also installed.

Klosterfrau Berlin

Klosterfrau Melissengeist

Medical Lozenges – 2.6 Million Pieces Daily

In fully continuous cooking systems, 2.6 million lozenges are produced daily. Ingredients are cooked in a two-stage process at temperatures up to 154 degrees Celsius. Active, color, and flavoring agents are dosed automatically according to individual product recipes.

What began in the 1980s with two batch cookers evolved into fully continuous production by the mid-1990s. Today, 6.5 tons of various lozenge brands leave production daily. Whether sugar-free or sugar-containing, in different colors and flavors – Klosterfrau Berlin is the central source for brands such as Neo-Angin, Anginetten, and Broncholind.

Production of medicinal bonbons in Berlin

Sterile Pre-Filled Syringes – Pioneering Since the 1970s

The sterile production of pre-filled syringes uses a special method, where both syringe content and inner packaging are sterilized in a single step. What started in the 1970s with small-scale industrial production of Instillagel, evolved by the mid-1990s into patented end-container sterilization.

A leap into the future came in the late 2020s with a fully automated filling and packaging line including sterilization. In 2025, a further fully automated system was installed on 1,200 square meters of cleanroom space with innovative energy-saving and recovery technologies. With an investment of 25 million euros, the foundations for the future of the Berlin site were firmly established.

The Klosterfrau Group Award

Since 2001, the International Klosterfrau Group Award for Research of Airway Diseases in Childhood has been awarded annually on the initiative of Prof. Dr. med. Dr. h.c. Dietrich Reinhardt, the International Klosterfrau Group Award for Research of Airway Diseases in Childhood has been awarded annually. Valued at 30,000 euros, the prize honors scientists whose research has significantly contributed to the basic research, diagnosis, and treatment of childhood asthma.